Basic Principles of Electric Desalination

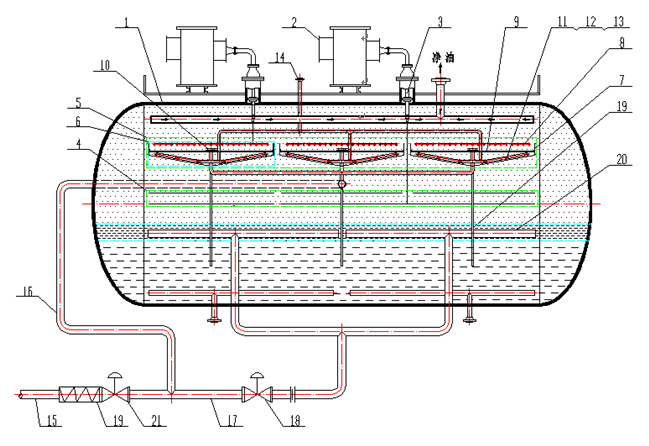

The working principle of electric desalination is to inject water into crude oil and mix with demulsifier, the water-soluble inorganic salt in the crude oil is also dissolved in water, and then the oil-water separation is carried out in the electric desalination tank, and the separation of oil and water in the electric desalination tank is used and installed The electrode in the electrostatic tank generates a high-voltage electric field, which polarizes the tiny water droplets in the oil. Under the action of the electric field, these charged water droplets collide with each other and coalesce into larger water droplets. Under the action of gravity, the larger water droplets freely settle to static electricity. A water layer is formed at the bottom of the tank, and the water-soluble inorganic salts in the crude oil will settle to the bottom of the electrostatic tank along with the water and discharged with the water. The larger solid particles can also quickly settle to the bottom to be separated. Part of the smaller solid particles (below 10µm) enters the water and settles.

Figure 1. The sedimentation mechanism of water droplets in the electrical desalination process

Whether the electric desalination equipment can meet the required technical indicators after it is put into operation depends on the following seven factors:

● Suitable electric field strength of strong electric field and weak electric field

● Appropriate demulsifier and injection volume

● Suitable operating temperature

● Appropriate water quality and injection volume

● Appropriate mixing intensity

● Suitable and stable oil-water interface

The rising speed Ws of the oil-water emulsion in the electric field (also can be converted into the residence time in the electric field)

If the above seven factors are relatively reasonable, the effect of electrical desalination will definitely reach the expected technical indicators. Among the seven factors, the seventh factor is the rising speed Ws of the oil-water emulsion in the electric field (which can also be converted into the residence time in the electric field), which has been determined when the size of the electric desalination tank is designed. It cannot be adjusted during operation. The remaining six factors can be adjusted during equipment commissioning or operation.

Introduction of various electric desalination technologies

1. Alternating current desalination and dehydration technology

Alternating current desalination and dehydration technology is the earliest electric desalination and dehydration technology introduced in my country. Its structure is shown in the figure below. Generally, three layers of horizontal electrode plates are arranged in the electric desalination tank. The first and third electrode plates are grounded, and the second layer The electrode plates are charged (there are also only two electrode plates), so that a weak AC electric field and a strong AC electric field are formed in the electric desalination tank.

Alternating current desalination and dehydration technology has a simple structure and is easy to install. It is especially suitable for devices with small processing capacity and small tank size. However, compared with AC and DC desalination and dehydration technology, it consumes more power and has low space utilization in the tank.

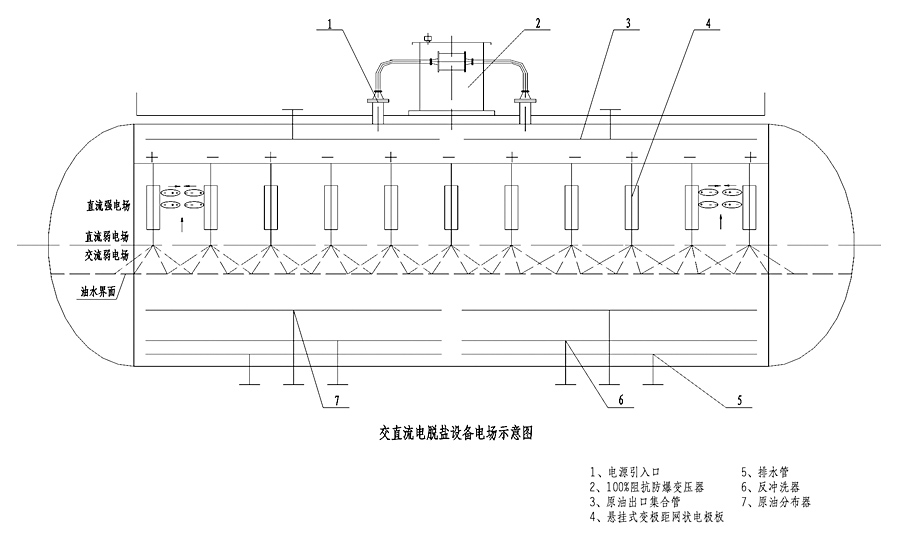

2. Alternating and direct current desalination and dehydration technology

AC and DC electric desalination and desalination have high efficiency, low power consumption, and a wide range of adaptation to raw oil. It is currently widely used in crude oil desalination in major refining and chemical enterprises.

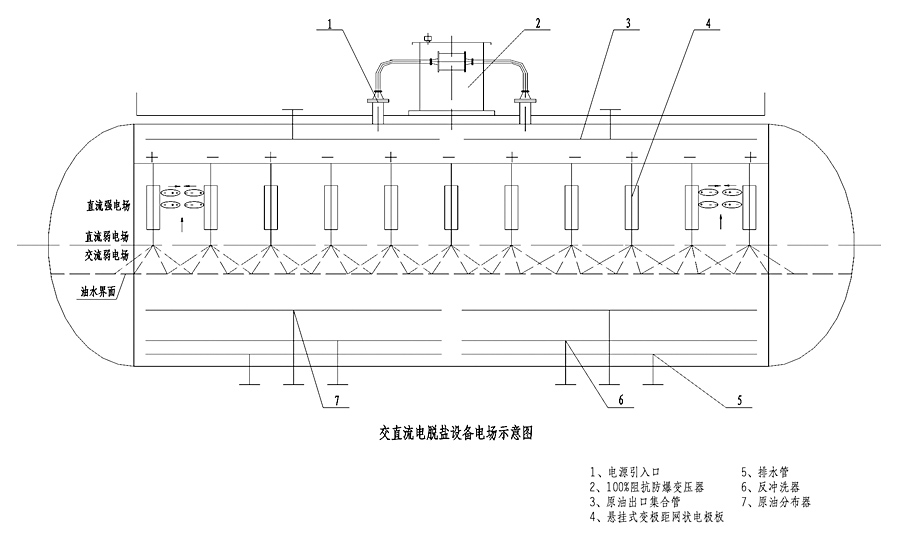

In the design of AC and DC desalination, AC weak electric field, DC medium electric field, and DC strong electric field are designed. In the desalination tank, the water content gradually decreases from bottom to top. According to the conductivity of the medium, a weak electric field is used to remove larger water droplets, which will reduce the entry of larger water droplets and emulsions into the medium and strong electric fields, that is, The use of a weak electric field can reduce power consumption and the occurrence of electric field short-circuits caused by the arrangement of larger water droplets, and effectively use the DC electric field and strong electric field to pull out tiny water droplets and reduce power consumption. At the same time, the application of this technology ensures that the water droplets have enough water in the electric field. The residence time is conducive to the effective separation of water droplets. In addition, the positive and negative plates in the DC power circuit are both half-wave voltages, and the two plates do not directly form a loop. The DC voltage on each group of electrodes is only 45% of the AC voltage, and there is only electric current between the plates during the discharge process. , Which greatly reduces the power loss, only half of the usual full-wave rectification form. However, because there is a certain capacitance between the electrode plates, there is actually a delay in the voltage drop of the positive and negative electrode plates, so there is an electric field between the electrode plates. This is also the essential reason why AC and DC power desalination equipment saves electricity compared to AC power desalination equipment.

Layout of the electric field in the AC and DC desalination tank

The greater advantage of AC and DC power desalination and dehydration technology is that the gradient electric field is arranged in the electric desalination tank, and the half-wave rectified electric desalination transformer is used. The power saving effect is obvious. In order to control the rising speed of crude oil in the electric field, the tank body is extremely large and the investment is high.

3. Advection squirrel cage electric desalination and dehydration technology

Advection squirrel-cage electrical desalination and dehydration technology is to arrange multi-layer squirrel-cage electrode plates in the electrical desalination tank, and a gradient electric field is formed in the electrical desalination tank. Head in and out of oil. The greater advantage of advection squirrel-cage electrical desalination and dehydration technology is that the electrical desalination tank is filled with electric fields and has a high utilization rate. However, due to the advection type of oil, the flow rate of the crude oil in the electric field is high, so the dehydration efficiency is low, and it can only be used for the dehydration of crude oil that does not require high dehydration. The water content of the crude oil after removal is generally between 0.5% and 1.5%. Electric desalination of crude oil with high dehydration requirements cannot be used.

4. Deep electric desalination and dehydration technology for heavy oil

The deep desalination technology of heavy oil is a new technology developed to adapt to the heavy quality of oil products and the desalination of 180# heavy fuel oil in gas turbine power plants. Its main feature is to adapt to a wide range of oil products, and the specific gravity of processed oil products can reach 0.98,50. The viscosity is as high as 180cst at ℃; the desalination and dehydration efficiency is high, the Na+k content of the treated 180# heavy combustion oil after removal is less than 0.5ppm; the demulsifier has a wide application range. The deep desalination technology of heavy oil has strong advantages in processing heavy oil.

The technology has the following characteristics:

1) The oil inlet distributor is installed between the horizontally installed upper and lower combined electrode plates. The horizontally installed upper combined electrode plate is electrified, and the horizontally installed lower combined electrode plate is grounded. After the raw oil comes out through the distributor, due to When the oil is fed in a strong electric field, the water droplets in the feedstock oil quickly coalesce into large water droplets and settle, the feedstock oil rises, and the droplet settlement and the feedstock rise almost do not interfere with each other, which greatly improves the dehydration efficiency of the feedstock oil.

2) The oil feeding method is the strong electric field. The strong electric field has the effect of strengthening the demulsification. After the raw oil enters the strong electric field, the oil and water can be separated quickly.

3) The oil intake method is the strong electric field oil intake. Due to the auxiliary demulsification effect of the electric field, the emulsified layer in the tank is thinner, and the lower electrode plate is grounded, which can maintain a higher oil-water boundary, and the water stays in the tank for a longer time. , To ensure that the drainage does not carry oil.

4) The oil inlet distributor has a special structure. After the raw oil is sprayed through it, a thin film is formed, which can be evenly distributed in the entire desalination tank without channeling. This can greatly improve the efficiency of the electric desalination tank.

5) The use of high-efficiency mixing equipment (static mixer + mixing valve) maintains a high mixing pressure difference, ensuring that the oil, water, and demulsifier can be fully mixed, so that the water can be evenly distributed in the oil in the state of fine droplets According to the formula of the coalescence force of the water droplets in the electric field, this can greatly improve the coalescence force of the water droplets. In addition, even mixing can better "wash" the salt in the raw oil.

6) An emulsion remover is installed in the electric desalination tank, which can discharge the emulsion in the tank in time without stopping work and returning the oil, ensuring the normal operation of the electric desalination device.

7) The heavy oil deep electric desalination technology combined with Party B's own process technology can ensure the normal operation of the heavy oil electric desalination system, and all technical indicators after the removal meet the requirements of the technical agreement.

However, this technology is the same as AC and DC desalination technology. When it is used for heavy crude oil or easily emulsified crude oil and the processing capacity is particularly large, in order to control the rising speed of crude oil in the electric field, the tank body is particularly huge and the investment is high.

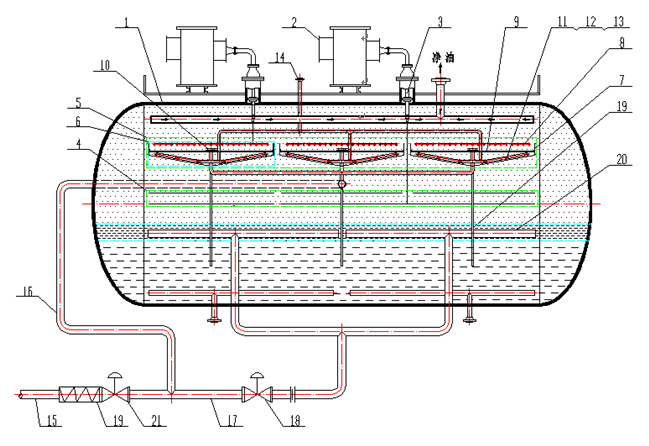

5. High-speed electric desalination technology

High-speed electric desalination technology is a new technology developed in recent years to adapt to the large-scale refinery. Its main characteristics are small tanks and large crude oil processing capacity; especially when the old equipment is expanded and transformed, it can be used in the original tanks. Under the changed situation, the internal structure can be transformed to achieve a higher processing capacity. However, according to the operation of high-speed electric desalination in several refineries, the oil product works well when the oil is lighter and the salt content before removal is very low. After removal, it can reach the technical index of 3mgNaCL/L. /cm3), the desalination ability is poor, and sometimes even the power cannot be delivered normally. For example, after Shanghai Jinshan Petrochemical introduced high-speed electric desalination, it has been unable to operate normally and had to be scrapped. The fatal weaknesses of high-speed electrical desalination are:

① Arrange several groups of independent units composed of upper electric field and lower electric field in the electric desalination tank. In each unit, the same oil inlet pipe is provided with oil inlet nozzles in the upper and lower electric fields. All the oil inlet nozzles of the electric desalination tank are not adjustable when the equipment is running. It cannot ensure that the flow rate of the oil-water emulsion sprayed by all the nozzles is the same when the processing capacity changes or the oil product changes. (see picture 1)

②Take any electric desalination unit in the electric desalination tank as an example, the high-speed electric desalination oil is divided into two electric fields, the upper and lower electric fields, and the lower electric field is equivalent to a low-speed electric desalination, which is not a big problem. However, in the upper electric field, after the floating crude oil in the lower electric field and the crude oil in the upper electric field merge, the ascent speed is greatly increased, which will carry salty water droplets out of the electric desalination tank. This is the salt content of the crude oil after high-speed electric desalination. The essential reason (see figure below).

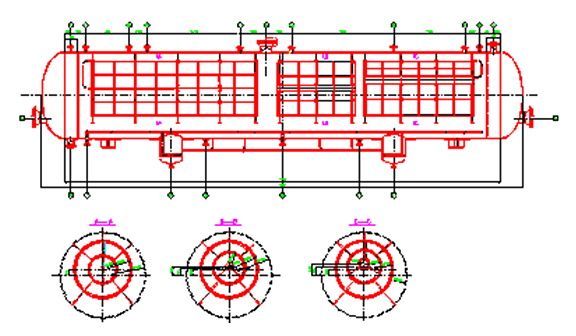

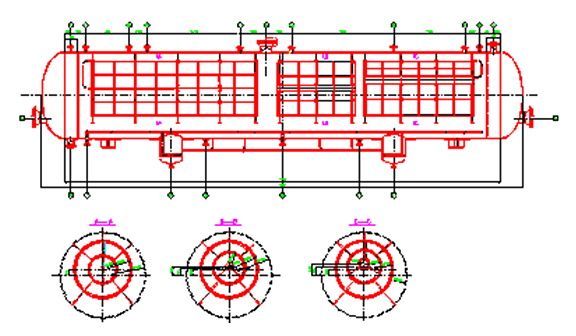

6. Electric desalination and dehydration technology with double oil inlet and double electric fields

In the internal structure of the equipment, the high-efficiency crude oil desalination and dehydration technology with dual oil inlet and dual electric fields makes full use of the unused space in the upper part of the electric desalination tank. The upper electric field composed of several sets of semi-closed disc electrodes is arranged, and the single electric field is changed The upper and lower two low-speed electric fields, which are not connected to each other, improve the efficiency of space use in the original electric desalination tank. Since the crude oil processed per unit time is distributed to the upper and lower low-speed electric fields for treatment, the rising speed Ws of the oil-water emulsion in the electric field is reduced. By changing the original single pipe to supply oil to two oil supply pipelines that supply oil to the upper electric field and the lower electric field respectively, as shown in the figure below. Through the above method, when the nature and processing volume of crude oil change, or according to the crude oil treatment effect of the upper and lower electric fields, the flow control valves on the two oil supply pipelines outside the electric desalination tank can be adjusted so that the upper and lower electric fields are respectively ideal The processing capacity can achieve the purpose of high-efficiency desalination and dehydration.